Description

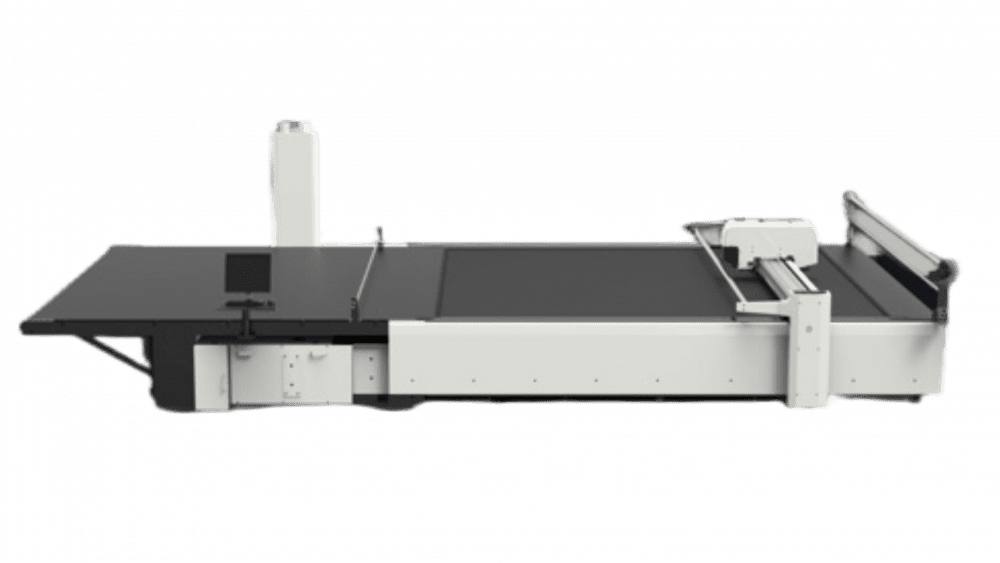

HIGH PLY, HIGH PRECISION, HIGH SPEED AUTOMATIC CUTTING MACHINE

MAJOR ADVANTAGES

- Japanese Technology and Parts

- Lowest Cost on Market

- Low Maintenance

- Extremely Low Down Time

- High Quality and Reliability

- Dedicated Technical Support

Yin’s HY-HC automatic computerized cutting system is specifically designed for your mass production cutting needs. Optimized with reciprocating knife technology. The HY-HC automated fabric cutter provides precise results while operating at high speeds, producing an effortless array of lines, shapes, and arcs.

This high-precision cutting system will always cut with accuracy for any single, low, and high-ply cutting jobs. The HY-HC offers the most flexibility for practically all industrial and technical fabrics currently used in the apparel, footwear, luggage, automotive, and furniture upholstery industries. Additionally, Yin’s cutting machines are proven solutions for the packaging, aerospace, and marine industries, along with the most difficult-to-cut materials.

The HY-HC automatic cutting machine is designed and integrated with Japanese technology machined to the most precise specifications including the computer, the electrical equipment, the motor and the drivers. Yin’s large scale production cutter technology has proven itself of being highly accurate, fast, but more importantly highly dependable. The HY-HC automatic cutting machine will help optimize your production while minimizing material waste and offering better time management. This is a particularly important solution for companies working with high cost materials (more efficient use of the raw material)

Our systems are fully customizable with your business in mind. We are able to provide equipment in the lengths, widths, and cutting heights that are best suited for your needs along with optional equipment that will make your cutting room solution be perfectly tailored for your business to succeed.

AWARD WINNING JAPANESE TECHNOLOGY

- State-of-the-Art Japanese technology backed by 40 years of cutting experience.

- Reputable Japanese made parts

- Thousands of satisfied clients Worldwide

- Gold Award- HY-HC automatic cutting machine was awarded the 19th China International Exposition Gold Medal. This is an prestigious honor awarded to a product that features the newest trends and innovations amongst equipment manufacturers.

LOW MAINTENANCE – MAXIMUM RUNTIME

- Straightforward Design – Very little maintenance is required due to the well engineered design.

- Bristle-Block conveyor bed- The cutting bed is made up of durable bristle blocks that can’t be damaged by the reciprocating knife during cutting. These slide in bristle blocks are very simple to replace. The bristle-block conveyor bed along with the automatic bristle cleaning add to what make the HY-HC a low maintenance machine.

- Self Sharpening- Equipped with our patented diamond double-wheel sharpener for longevity and a precise cut. Automatically grinds out the blade evenly with adjustable grinding intervals for different materials to ensure the accuracy of cutting without sacrificing cutting speed.

- Vacuum Chamber- The HY-HC automatic cutting machine is integrated with an enclosed vacuum chamber that will keep the fabric stable while cutting to improve your accuracy. The vacuum will reduce air leakage as much as possible which cut down on the lint being released into the air. This intelligent feature will save you maintenance time and give you longer lasting equipment.

- Robust Belt Drives- Includes belt drives for axial movement rather than chains or linear actuators resulting in longer life

- Dust Collector- Integrated into the vacuum chamber is an dust collector which accumulates scrap material to send to the trash can.

EASY-TO-USE

- User-Friendly Technology- HY-HC’s automatic cutting machine doesn’t require any specific technical expertise, making it painless to use and operate. The operating system is simple and helpful.

- Automatic Troubleshooting, and Diagnosing- Intuitive machine equipped with a self-diagnosing feature (when an error occurs, the screen automatically reports it’s error code); effective for quick troubleshooting and reduced downtime. HY-HC’s smart feature even notifies you when it’s time to change your tools.

- Automatic Cloth Alignment Correction- Our software keeps your production on schedule even when your material feeds in at an angle. The cutting machine will adjust itself automatically to keep your cut quality perfect.

- Automatic Conveyor Load Assist- Reduce your manual handling time with the conveyor assist. The HY-HC automatic cutting machine will move your material from the spreading table to the cutting area while the vacuum is on and subsequently moves your cut pieces to pick up table after cutting .

HIGH RETURN ON INVESTMENT

- Lowest Cost on the Market- Best automatic cutting machine for the money without sacrificing quality

- Fabric Utilization- When you are working with expensive technical textiles and advanced composites, it is crucial to use as much as possible. With the HY-HC, you can select the starting point so that the entire material is optimized, resulting in zero-gap cutting.

- Reporting Management System- Improve your management efficiency by utilizing the daily and monthly reports. After reviewing your cutting time, cutting speed, and cutting marker quantity you can communicate accurate production times and maximize your runtime.

- Space- One automatic cutting machine can save the space from 3 manual cutting consoles.

- Maintenance- HY-HC’s automatic cutting machine is extremely low maintenance and you’ll produce more and improve your quality in less time.

- Labor- Up to 75% reduction in labor costs.

- Very Low Downtime

SOFTWARE FEATURES

- Windows® operating system

- MarkEdit and CutterControl software included with every automatic cutting system

- Barcode system-MarkEdit software can export your marker information into a barcode to make automatic cutting optimized -maximizing cutting accuracy, speed, and production management

- Import standard industry files– DXF, HPGL, ISO RS274d, NTV, ESSI

- Includes 5 levels of material melting mitigation to prevent your fabric from melting

- Vacuum has 7 levels of intensity vacuum used for different plys and materials

- Notch identification and transformation

- Drill hole identification and transformation

- Cut line proximity awareness

- Reporting management system- includes marker, daily and monthly reports

ADDITIONAL FEATURES

- Powerful Exhaust- Reduces dust and improve your production environment

- Drilling Device- Customizable drilling punches 2-25 mm holes for use in car seats, interiors, hats, luggage, bags, etc.

- Quiet Design- Reduces the noise in your cutting room

- Solid and Reliable Machinery

- OSHA Certified

OPTIONAL FEATURES

- Cooling Device: Helps keep the blade when working with fabrics with a low melting point

- Movable Cutter with Rails: Can be used when working with multiple spreaders. The operator uses the software to select the spreader with the required material. Allows continuous operation of the cutter without waiting for the fabric laying process.

- Additional 2 Drills: Secondary drilling unit for drilling multiple hole sizes simultaneously

- Additional 3 Drills: Additional drilling units for drilling multiple hole sizes simultaneously

- Heavy Head for Dense Materials: Added heavy duty motor and axle to cut the heaviest of materials such as denim

- Barcode Reader: Immediately access the information in your cut file

- Extra Long Cutting Bed- Specialty 3.2 Meter bed size for extra long materials