Address

10335 Brockwood Rd

Dallas, TX 75238

Work Hours

Monday to Friday: 9AM - 5PM

INDUSTRIAL FABRIC CUTTING MACHINE Introducing Yin’s HY-S Single-Ply to Low-Ply…

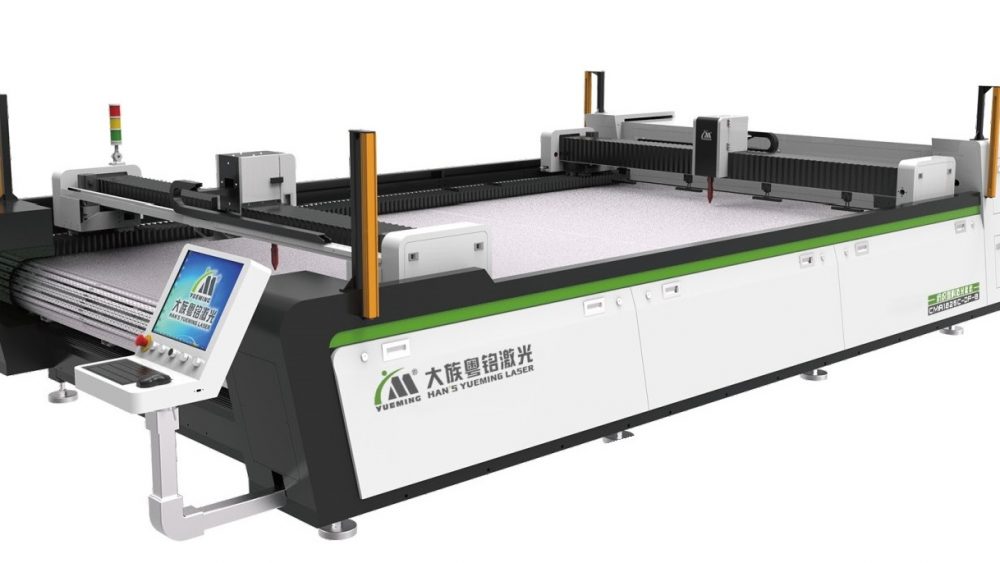

Flat Bed Laser for Large Materials

Specializes in Small Leather Hide Cut, Imitation Leather, & Composite…

Introducing the CMA Laser Cutting Machine: Your ultimate solution for…

Experience the ultimate precision and efficiency in fabric cutting with our state-of-the-art automatic cutting machines. Our CNC cutters, also known as a CNC fabric cutting machine, employs cutting-edge CAD technology to create intricate patterns and shapes with unparalleled accuracy. Whether you’re in the garment, industrial, automotive, aerospace, furniture industries, or beyond, our CNC cutting machines ensures faster production times and minimizes waste by eliminating human error.

Unlock a world of possibilities with our CNC digital knife cutting machines. Intricate designs that once required hours of manual labor can now be achieved in record time. This revolutionary technology empowers you to craft unique patterns with exquisite detailing, giving your creations a distinctive edge.

Our innovative fabric cutting machines redefine versatility, allowing manufacturers to incorporate a wide range of materials into their designs. From luxurious leather to soft cotton and everything in between, you have the freedom to experiment with various fabrics. Explore the realms of fashion with materials like classic denim and delicate silk, giving your designs the perfect touch.

For manufacturers that cut and sew their product line, our CNC digital knife cutting machines are a game-changer. Rapidly prototype your ideas and seamlessly execute production runs, bringing your products to market at an unprecedented pace. Embrace efficiency and watch your designs come to life faster than ever before.

At the heart of clothing and apparel production lies automatic fabric cutting machines that breathe life into fabrics. Our cutting-edge devices offer reliability and accuracy, effortlessly transforming fabrics into customized pieces for your garments. Our industrial machinery are offered with a range of knife blades and tools to help revolutionize your workflow. Enhance efficiency, reduce material waste, and minimize manual labor costs, all while achieving remarkable results.

Production teams can choose from a variety of cutting technologies tailored to their unique needs, each offering distinct benefits based on project requirements. Embrace the power of modern tools and elevate your productivity to new heights across various sectors. Join the ranks of successful manufacturers who have harnessed the potential of cutting-edge technology to transform their organizations.

Experience unparalleled versatility and efficiency with our automatic fabric cutting machines. Designed to adapt to your ever-changing project needs, these machines offer a level of flexibility that revolutionizes your workflow.

Imagine seamlessly transitioning between different tools to tackle diverse materials and intricate designs. With our modular cutting machines, you have the power to customize your setup, allowing you to switch out tools effortlessly. This adaptability means you can take on a wide range of projects without the need for multiple specialized machines, saving you time, space, and resources.

Whether you’re working on textiles, plastics, composites, or other materials, our modular cutting machines ensure you’re always equipped with the right tool for the job. Embrace the future of cutting technology and experience the freedom to innovate, create, and transform with unmatched precision and ease.

| Cutting Width | 62.99”, 70.87”, 78.74”, 86.61” |

|---|---|

| Cutting Length | Cutting Length: Conveyable 98.42” |